Works commenced on the a533 Expressway Bridge Replacement project took place in January 2022. The purpose of National Highways’ scheme was to replace the concrete bridge with a new 67m two-span concrete bridge. To minimise disruption, the existing bridge will remain open whilst the new bridge is constructed offline.

Upon completion of the new structure, traffic will be transferred, and the contractor will demolish the existing bridge. The new bridge has been designed to allow for an additional junction and lanes if required in the future.

MGF engaged early with the principal contractor in November 2020 through an existing relationship with Amey Sir Robert McAlpine. Temporary works requirements included excavation support for the central pier (central reserve M56) and the abutments within the earth embankments.

Following the issue of outline designs and to demonstrate capability as a supplier, a virtual learning session was carried out which included members of the design and proposed site team in December 2020.

A533 Expressway Bridge Replacement

Amey Sir Robert McAlpine for National Highways

Rob Eagles, Regional Engineering Manager

A collaborative approach allowed for the early agreement of a temporary works solution

Using a collaborative approach throughout the project, MGF were able to finalise the temporary works prior to works commencing on site. This had benefits such as delivering a value-led solution, cost certainty, and a fair tender process for subcontractors.

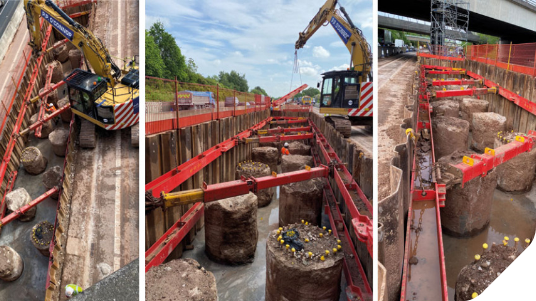

The Central Pier is a 23m long x 3.89m wide x 2.50m deep two-frame solution consisting of ER750/8 trench sheets, 254UC brace, and 200 series cross struts. A propped cantilever has been adopted for the East Abutment and is approx. 23m long x 7.94m wide x 2.40m deep, consisting of KKD600/8, a 254UC brace and a combination of 200/300 series cross struts.

The scheme included a requirement to locate the temporary props between the permanent piles to allow access and practicality to break down to pile cut-off level. Due to the surrounding hazards, MGF used 3D imagery to demonstrate the interaction between temporary works and existing structures.

Due to on-site restrictions for the East Abutment, a detailed installation sequence was required. This included working within the constraints of the cofferdam and excavating back to an access point, changing the strut layout at a particular stage to prevent issues later in the construction programme during the removal.

A technical query was raised by National Highways in relation to the steel grade of the trench sheets for the Central Pier. This was overcome by specifying the ER750/8 instead of the KKD600/8 and duly accepted.

A key benefit to the principal contractor was understanding the temporary works requirements, finalising them prior to commencing on-site works. This removed all pressure in preparation, design, checking, and ordering of the temporary works equipment. The collaborative approach between the principal contractor, sub-contractor and supplier with on-site meetings guaranteed the buy-in from all parties throughout.

The close working relationship between MGF, Amey Sir Robert McAlpine and PP O’Connor has allowed for the efficient planning and execution of the temporary works, with the current completion date set for summer 2023.

For the latest updates on the scheme, visit the A533 Expressway bridge replacement webpage.

Our 200 series strut is a highly versatile, medium duty strut system primarily for use in conjunction with hydraulic bracing …

Designed to brace medium to large cofferdams and trenches, allowing safe installation of large underground structures, deeper drive/thrust pits or …

Whether you have a question, need a quote, or want to discuss a project, our dedicated team is ready to assist you.