The St Michael’s development is an ambitious joint venture between Relentless and Salboy, led by Gary Neville and Simon Ismail. This landmark project aims to create one of Manchester’s largest buildings and one of the most distinctive and recognisable high-rises in the UK. A crucial component of this vision involved constructing a circa 12.50m deep three-storey basement structure.

Given the site’s location in Manchester City Centre, surrounded by historically significant heritage buildings, maintaining safety and structural integrity for neighbouring properties was paramount.

MGF was selected to support this £400 million development, contributing to the design and implementation of excavation support solutions.

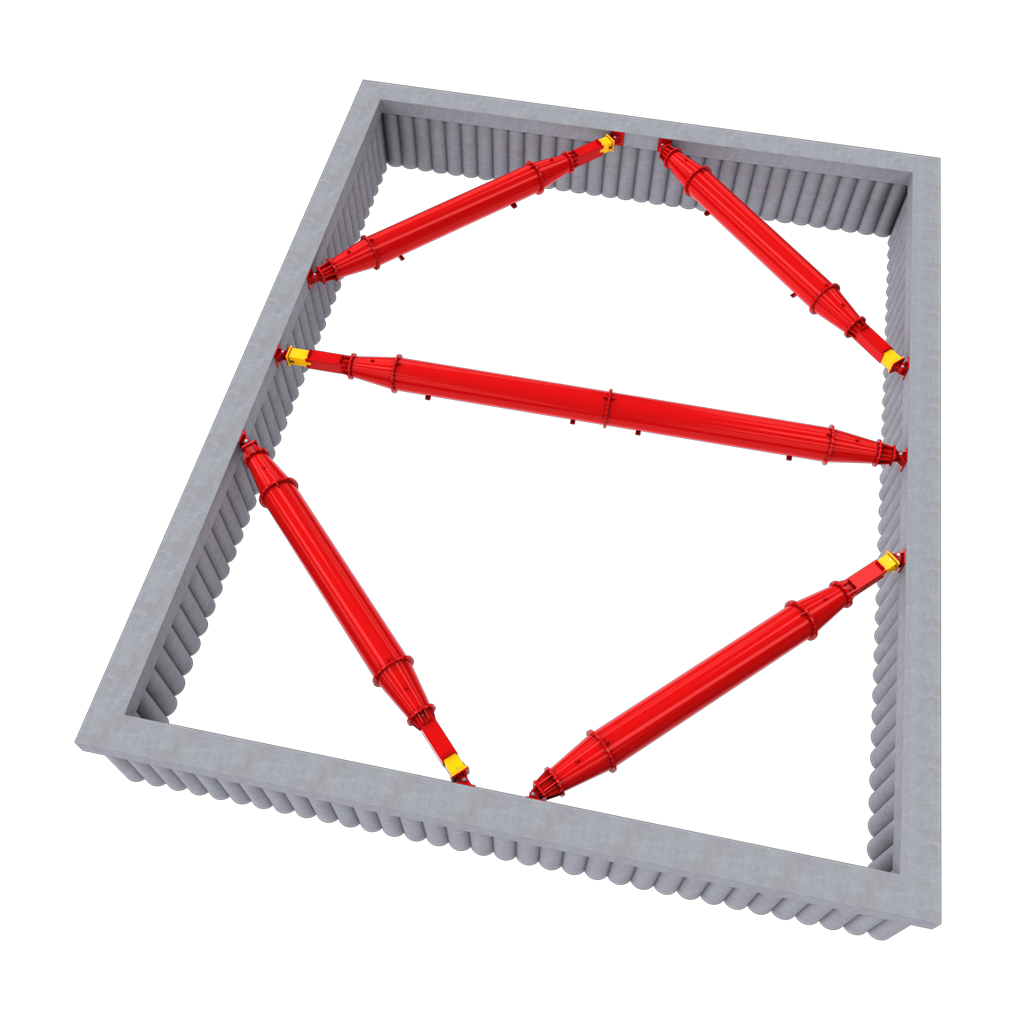

Collaborating closely with Mayo Civils, the project’s subcontractor, MGF developed a detailed, structurally sound, and efficient propping system to facilitate the construction of the basement.

St Michael’s, Manchester

Domis (Main Contractor) Mayo Civils (Sub Contractor)

John Maguire, Technical Sales

Minimal props – maximum working room

The St Michael’s project presented several complex challenges during the design phase:

The design for St Michael’s required strategic placement of tower cranes to maintain a sufficient working radius while avoiding oversailing into adjacent properties, which would incur additional costs. The crane locations were fixed, necessitating an innovative design to avoid clashing with the tower cranes.

The project plan involved jump-forming the core walls past the propping system before the props were removed. This required the integration of large-span walers with a propping arrangement to keep clear of the building cores whilst maintaining structural integrity and minimising lateral wall movements.

The excavation site was situated close to the Sir Ralph Abercromby pub on the south-east elevation, a heritage building of historical significance. A ground movement assessment was conducted to evaluate potential impacts on surrounding assets, ensuring that MGF’s propping solution would mitigate risks of settlement or structural movement.

During the mobilisation of MGF’s equipment, there was an amendment to the basement’s design requirements. This demanded rapid design adjustments and the customisation of equipment to accommodate the new footprint. This needed to be done without compromising on safety or project timelines.

The St Michael’s project was uniquely challenging due to its location in one of the busiest and most densely populated areas of Manchester. Surrounded by culturally significant heritage structures, precision and care were crucial to avoid disruptions to the local community and infrastructure.

Innovative Propping Strategy

To maximise working space and accommodate the fixed positions of tower cranes, MGF’s engineering team devised a minimalistic propping design. This approach enhanced operational efficiency while maintaining structural stability. The strategy also enabled seamless core wall construction without interference from the propping system.

Advanced Propping Equipment and Logistics

MGF deployed a sophisticated combination of equipment to meet the project’s requirements:

This solution required meticulous logistical coordination among MGF’s Transport, Operations, and Engineering teams to deliver and install multiple 11.50m tank brace sections and prop components within the confined city-centre site.

MGF’s innovative propping solution facilitated the successful excavation for the 12.50m deep three-storey basement structure. The project was delivered efficiently, adhering to tight deadlines and maintaining the safety and stability of surrounding heritage structures.

MGF’s involvement in this high-profile St Michael’s project underscores its capacity to handle large-scale, complex urban developments. The collaboration with Mayo Civils and strategic problem-solving set a benchmark for engineering excellence. MGF is proud to contribute to the realisation of one of Manchester’s most iconic buildings and provide a solution for such a large-scale project.

The St Michael’s project showcases MGF’s expertise in excavation support and its ability to overcome complex urban construction challenges. By leveraging innovative design solutions, bespoke equipment, and seamless logistical execution, MGF played a pivotal role in the early stages of one of Manchester’s most ambitious architectural ventures. This case study illustrates MGF’s commitment to engineering excellence, safety, and strategic collaboration, reinforcing its reputation as a leader in excavation support solutions.

A heavy duty modular bracing strut system designed for use with 406 UC and T700 hydraulic bracing systems but can …

Our 600 Series Struts are heavy duty modular bracing strut system designed primarily for use with 305, 406 UC and …

Our 406UC Brace has been designed to brace large and deep cofferdams, these are frequently used on major basement and …

Whether you have a question, need a quote, or want to discuss a project, our dedicated team is ready to assist you.