Construction of the new multi-million-pound campus at the University of Ulster, Belfast, presented exciting challenges to MGF across several departments. This included research and development, design and engineering, manufacturing and the operational team who delivered the project from Head Office.

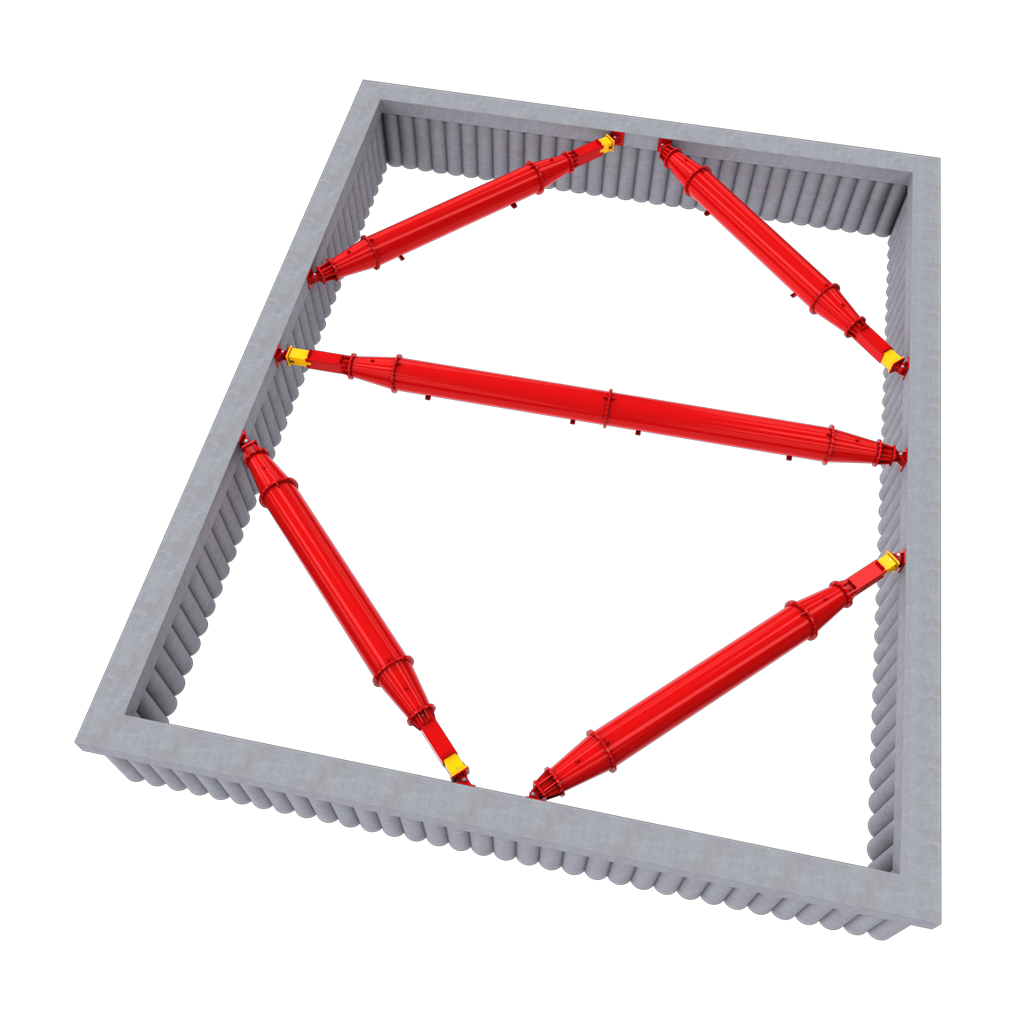

Working with a large specialist joint venture (SJV), MGF developed, designed and supplied a temporary works scheme comprising 406UC waling beams and large spanning props to support the new retaining walls. The temporary works scheme allows construction of the single biggest basement excavation MGF has ever supported.

“This is one of the biggest basement excavations we have ever supported. We are using equipment beyond the boundaries of what we usually use. There was a complex interaction between permanent and temporary works. The positioning of props conflicted with the locations of new cores, so the basement structure could not be completed. We worked with the permanent work’s designer and contractor to propose a sequence of works which used the newly constructed permanent works to provide support to the retaining walls. This was key in enabling the high-level props to be removed and construction to continue unimpeded.”

Stephen Barker, Engineering Director, MGF

Major Project: Construction of new campus at University of Ulster

SJV

Stephen Barker, Engineering Director

MGF developed, designed and supplied a temporary works

The team developed a heavy-duty prop that exceeded the capabilities of the 1000 series strut (the largest strut in the core hire fleet) to sustain the loadings imposed and span the required 47.3m. The workshop in Wigan, Greater Manchester, manufactured all the required bespoke components in conjunction with the construction programme.

Clashes between props and the proposed permanent works disrupted the construction of the cores. MGF worked closely with the SJV BIM team to ensure that clashes were identified before the University of Ulster construction began.

It was agreed to install a separate propping system below the upper level props, back propping the basement walls. This enabled the upper level props to be removed so that the basement construction could be completed.

The 400, 600, and 1000 Series strut systems were used as support to resist the loads and span the basement. A new propping system was developed to clear the longest span, 47.3m long clear end-to-end.

To add to the complications, the site is very restricted, with a busy city road to the west. All plans had to meet stringent performance criteria to achieve technical approvals from DRD Northern Ireland.

MGF supplied 728 tonnes of shoring equipment comprising 74 hydraulic props, 1088 metres of strut extension, 822 metres of steel waling and 275 waler support brackets to enable the construction of the basement structure.

Construction on the overall £250 million, 75,000 square metre Belfast campus is currently the largest building project in Northern Ireland.

Phase 2 saw two new blocks developed on York Street, directly opposite the existing campus building.

A heavy duty modular bracing strut system designed for use with 406 UC and T700 hydraulic bracing systems but can …

Our 600 Series Struts are heavy duty modular bracing strut system designed primarily for use with 305, 406 UC and …

Our 400 series strut is a highly versatile, heavy duty modular bracing strut system designed primarily for use with hydraulic …

Whether you have a question, need a quote, or want to discuss a project, our dedicated team is ready to assist you.